Bank 1 air fuel ratio imbalance presents a significant challenge for engine performance and efficiency. This issue, often stemming from malfunctions in fuel delivery, intake, ignition, or exhaust systems, can lead to a variety of noticeable symptoms. Understanding the causes, diagnostic procedures, and repair strategies is crucial for effective troubleshooting and maintenance.

The imbalance can manifest in reduced power output, rough idling, and potentially damaging emissions. Accurate diagnosis hinges on meticulous analysis of sensor readings, diagnostic trouble codes (DTCs), and a systematic evaluation of each component within the affected engine bank.

Causes and Contributing Factors

A persistent air-fuel ratio imbalance in Bank 1 of an engine necessitates a thorough investigation into the various potential sources. Ignoring these underlying issues can lead to diminished performance, increased emissions, and potentially severe engine damage. This analysis delves into the key areas impacting the air-fuel mixture, focusing on the fuel delivery, intake, ignition, and exhaust systems.

Fuel Delivery System Issues

Proper fuel delivery is paramount for maintaining an optimal air-fuel ratio. Malfunctioning fuel injectors, clogged fuel filters, or issues with the fuel pump can directly impact the amount of fuel reaching the combustion chamber. For example, a fuel pump that is underpowered or intermittently failing will deliver less fuel than expected, resulting in a lean air-fuel ratio. Conversely, a leak in the fuel lines or a faulty injector delivering excessive fuel will result in a rich mixture.

This imbalance can be compounded by incorrect fuel pressure regulation. Furthermore, worn or damaged fuel injectors may spray fuel unevenly, leading to discrepancies in the air-fuel ratio across cylinders.

Intake System Impact

The intake system’s role in maintaining the air-fuel ratio is crucial. Airflow restrictions, such as a clogged air filter or a restriction in the intake manifold, can reduce the volume of air reaching the combustion chamber. This inevitably leads to a lean air-fuel ratio. Conversely, a leak in the intake system can cause an increase in the amount of unmetered air entering the engine, which disrupts the balance.

A faulty or damaged throttle body can result in an inaccurate measurement of the airflow, impacting the ratio. For instance, a throttle body that sticks open will allow more air than intended, creating a lean condition.

Ignition System Problems

The ignition system’s functionality plays a critical role in combustion efficiency, and thus, the air-fuel ratio. Misfiring cylinders due to faulty spark plugs, a malfunctioning ignition coil, or a problem with the distributor (if applicable) can result in an irregular air-fuel mixture. For instance, a faulty ignition coil can cause inconsistent spark strength, leading to incomplete combustion and a lean or rich condition, depending on the cylinder’s response.

Exhaust System Concerns, Bank 1 air fuel ratio imbalance

The exhaust system, while not directly responsible for maintaining the air-fuel ratio, can contribute to the issue. Catalytic converter issues or exhaust leaks can affect the exhaust pressure, impacting the overall engine performance. A blocked or restricted exhaust system can cause backpressure, affecting the engine’s ability to effectively draw in air, which can indirectly affect the air-fuel ratio.

Exhaust leaks can also influence the overall fuel-air ratio through changes in exhaust pressure, which may affect the engine’s ability to draw in air effectively.

A bank 1 air fuel ratio imbalance can sometimes stem from various issues within the engine’s system. Fortunately, maintaining a healthy lifestyle, including exploring natural remedies like bbl tea for weight loss, bbl tea for weight loss , might contribute to overall well-being, indirectly influencing engine performance and potentially aiding in resolving the imbalance. However, a proper diagnosis and repair by a qualified mechanic are crucial for addressing the root cause of the bank 1 air fuel ratio imbalance.

Comparison of Mechanical Problems and Their Effects on Bank 1 Air-Fuel Ratio

| Mechanical Problem | Effect on Bank 1 Air-Fuel Ratio |

|---|---|

| Clogged Air Filter | Lean Mixture |

| Fuel Injector Malfunction (Spraying Too Little Fuel) | Lean Mixture |

| Fuel Injector Malfunction (Spraying Too Much Fuel) | Rich Mixture |

| Intake Leak | Lean Mixture |

| Faulty Spark Plug | Lean or Rich (depending on cylinder) |

| Exhaust Leak | Potentially Lean or Rich, depending on location and size |

Repair and Troubleshooting Strategies

Correcting air-fuel ratio imbalances is crucial for optimal engine performance and longevity. Ignoring these issues can lead to significant damage and costly repairs down the line. A precise understanding of the repair process, including proper injector adjustment and air intake system maintenance, is paramount.Effective troubleshooting hinges on systematic evaluation of various components. This involves a methodical approach, moving from initial checks to more in-depth diagnostics as needed.

Troubleshooting must be based on a solid understanding of the specific engine’s design and characteristics.

Fuel Injector Adjustment

Precise fuel injector calibration is critical for achieving the ideal air-fuel ratio. Incorrect injector settings can result in poor combustion, reduced power output, and increased emissions.The procedure for adjusting fuel injectors involves careful manipulation of the injector pulse width. Manufacturers provide specific guidelines for each engine model, including the required tools and tolerances. Improper adjustment can lead to significant performance problems.

A bank 1 air fuel ratio imbalance can sometimes be a tricky issue to diagnose, potentially impacting the performance of your vehicle. Fortunately, if you’re looking for a new home in a desirable location, you might consider exploring properties for sale in Lake Hickory, such as those available at lake hickory houses for sale. Understanding these imbalances in your vehicle’s fuel system is key to maintaining optimal engine function.

Specialized diagnostic equipment, like oscilloscopes, may be necessary for fine-tuning injector timing and pulse width for optimal performance. Experienced technicians are crucial for this task, as incorrect adjustment can result in significant engine damage.

Air Intake System Inspection and Cleaning

A clean and unobstructed air intake system is essential for proper engine function. Clogged air filters, restricted air passages, or other obstructions can disrupt the air-fuel mixture, causing imbalances.Thorough cleaning and inspection of the air intake system are necessary. This includes inspecting the air filter for debris and replacing it if necessary. Inspecting the air intake hoses for kinks, cracks, or obstructions is also critical.

Additionally, ensure the air intake manifold is free from leaks or restrictions. Regular maintenance of this system is essential to prevent performance issues and costly repairs.

Troubleshooting Table

| Troubleshooting Step | Expected Outcome | Potential Solutions |

|---|---|---|

| Inspect air filter for debris | Clean air filter, no debris | Replace air filter |

| Inspect air intake hoses for damage | No damage or obstructions | Repair or replace damaged hoses |

| Verify fuel pressure | Fuel pressure within manufacturer’s specifications | Address fuel pump issues, check fuel filter |

| Check injector pulse width using diagnostic equipment | Pulse width matches manufacturer’s specifications | Adjust injector pulse width according to manufacturer’s guidelines, or replace injector |

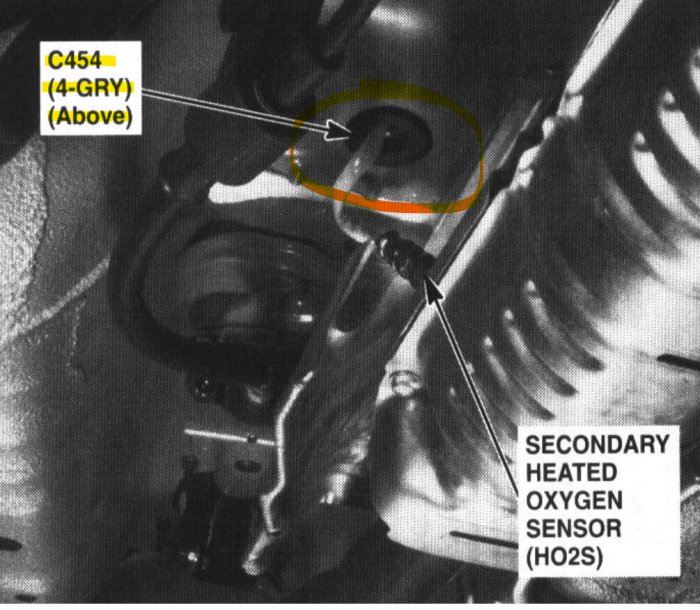

| Verify oxygen sensor readings | Oxygen sensor readings within range | Replace oxygen sensor |

Repair Methods Comparison

Different repair methods offer varying degrees of effectiveness and complexity. A proper diagnosis is crucial to choose the correct method. For example, simply replacing a faulty component like a fuel injector might resolve the issue, but a more comprehensive approach may be necessary if the issue stems from a broader system malfunction.Direct replacement of components is often the simplest solution, but a deeper analysis of the root cause is frequently required for a lasting resolution.

Repair methods vary in complexity, and a thorough understanding of the specific engine’s characteristics is critical to choosing the right strategy. Consider the cost and time involved with each method, balancing this against the potential for further issues or damage.

Prevention and Maintenance: Bank 1 Air Fuel Ratio Imbalance

Proactive measures are crucial in mitigating air-fuel ratio imbalances. Neglecting preventative maintenance can lead to significant engine damage, increased fuel consumption, and reduced performance. A comprehensive preventative approach, encompassing regular inspections and meticulous maintenance, is paramount for long-term engine health.Effective prevention hinges on understanding the interconnectedness of the fuel and air systems. A meticulously maintained system operates with optimal efficiency, minimizing the risk of imbalances.

This proactive approach translates to lower repair costs, extended engine lifespan, and improved overall performance.

Fuel System Inspections and Cleaning

Regular fuel system inspections are vital for identifying potential issues before they escalate. Contamination from water, sediment, or debris can severely compromise the fuel’s quality and delivery, ultimately leading to air-fuel ratio problems. Inspecting fuel filters, fuel lines, and fuel injectors for any signs of blockage or deterioration is essential. Prompt cleaning or replacement of contaminated components safeguards the fuel system from further damage.

Furthermore, regular cleaning of the fuel tank and sediment trap is essential to maintain optimal fuel quality and prevent potential clogs.

Air Filter Maintenance

Proper air filter maintenance is equally critical. Clogged air filters restrict airflow, causing the engine to compensate by adjusting the air-fuel ratio. This can lead to significant performance degradation and, in severe cases, engine damage. Regular air filter inspections and replacement, based on manufacturer recommendations, are imperative to maintaining optimal engine performance and preventing air-fuel ratio imbalances.

Inspecting the air filter for excessive dirt or debris is a critical first step, and immediate replacement is necessary if it is excessively clogged.

Preventative Maintenance Schedule

Consistent maintenance plays a pivotal role in preventing air-fuel ratio issues. A well-defined schedule ensures timely inspections and repairs, thus avoiding potential problems. The following table provides a detailed preventative maintenance checklist for the engine’s fuel and air systems.

| Component | Inspection Frequency | Action |

|---|---|---|

| Fuel Filter | Every 5,000 miles (or as recommended by the manufacturer) | Inspect for blockage or contamination; replace if necessary. |

| Fuel Lines | Every 10,000 miles (or as recommended by the manufacturer) | Visually inspect for cracks, leaks, or damage. |

| Fuel Injectors | Every 30,000 miles (or as recommended by the manufacturer) | Inspect for clogging; clean or replace as needed. |

| Fuel Tank | Every 20,000 miles (or as recommended by the manufacturer) | Drain sediment trap and clean fuel tank. |

| Air Filter | Every 5,000 miles (or as recommended by the manufacturer) | Inspect for excessive dirt; replace if clogged. |

Regular preventative maintenance, especially of the fuel and air systems, is a critical element in minimizing the risk of air-fuel ratio imbalances.

Final Thoughts

In conclusion, addressing a bank 1 air fuel ratio imbalance requires a comprehensive understanding of the engine’s intricate systems. A systematic diagnostic approach, combined with appropriate repair strategies and preventative maintenance, is essential to mitigate the issue’s impact on engine performance and longevity. Careful attention to fuel system integrity, intake efficiency, ignition timing, and exhaust functionality is paramount.

Questions Often Asked

What are the common symptoms of a bank 1 air-fuel ratio imbalance?

Common symptoms include reduced engine power, rough idling, hesitation, and potentially, misfires. Emissions may also be affected, leading to increased pollutants.

How can I identify the specific cause of the imbalance?

Thorough diagnostic procedures, including examining sensor readings, interpreting DTCs, and inspecting relevant components (fuel injectors, intake system, ignition system, exhaust system) are vital to pinpoint the root cause.

What tools are needed for diagnosing an air-fuel ratio imbalance?

Specialized tools such as diagnostic scanners, oscilloscopes, and air/fuel ratio meters, along with a thorough understanding of engine systems, are crucial for accurate diagnosis.

What preventative measures can I take to avoid future imbalances?

Regular maintenance, including fuel system inspections, cleaning, and proper air filter replacement, can help prevent future issues.